ما هو صمام IAC وكيف يعمل?

التحكم في الهواء الخمول (IAC) يعد Valve مكونًا مهمًا لنظام إدارة الخمول بالمحرك, خاصة في المركبات التي تستخدم جسم دواسة الوقود التي تعمل بالكابل.

ينظم صمام IAC كمية الهواء الذي يتجاوز لوحة الخانق عند إغلاق الخانق. هذا يضمن أن المحرك يحافظ على خمول مستقر في ظل ظروف مختلفة, مثل البرد يبدأ, التغييرات في تحميل المحرك (على سبيل المثال, تكييف), أو الانتقال من القيادة إلى الخمول.

وظائف رئيسية

- تنظيم تدفق الهواء: عندما يتم إغلاق الخانق, يسمح صمام IAC بكمية مكافحة من الهواء لتجاوز لوحة الخانق وإدخال مشعب السحب.

- التحكم في سرعة الخمول: يتم التحكم في الصمام إلكترونيًا بواسطة وحدة التحكم في المحرك (وحدة نقدية أوروبية), الذي يضبط الصمام بناءً على مدخلات مثل درجة حرارة المحرك, الحمل الكهربائي, وموقف الخانق.

- مساعدة بدء التشغيل: أثناء يبدأ البرد, يفتح الصمام أوسع للسماح بمزيد من الهواء في, رفع سرعة الخمول لمنع المماطلة.

مبدأ العمل

لفهم كيف يعمل صمام IAC, من المهم أن تعرف أن وحدة التحكم الإلكترونية تراقب بيانات المستشعرات (على سبيل المثال, درجة حرارة سائل التبريد, كمية الهواء) ويرسل إشارات إلى صمام IAC لفتح أو إغلاق وفقًا لذلك.

يتيح هذا اللائحة في الوقت الفعلي لحجم الهواء الذي يدخل مشعب السحب التحكم الدقيق في سرعة الخمول دون إدخال يدوي. يتفاعل النظام داخل المللي ثانية, إجراء تعديلات تلقائية حسب ظروف تشغيل المحرك.

أنواع صمامات IAC

- نوع السائر محرك: يحرك الصمام في صغيرة, خطوات دقيقة لتنظيم تدفق الهواء.

- عرض النبض المعدلة (PWM) يكتب: يستخدم نبضات كهربائية متفاوتة للتحكم في موضع الصمام بشكل مستمر.

يؤدون كلا النوعين نفس الوظيفة, لكن توافقها والأساليب التشخيصية تختلف حسب نموذج السيارة وبنية وحدة التحكم الإلكترونية.

الأعراض الشائعة لصمام IAC السيئ

التحكم في الهواء الخامل (IAC) غالبًا ما ينتج عن الصمام سلوك محرك غير مستقر أو لا يمكن التنبؤ به, خاصة في الخمول. فيما يلي خمسة من الأعراض الأكثر شيوعًا, جنبا إلى جنب مع أسبابهم والإجراءات الموصى بها:

أكشاك المحرك أثناء البدء البارد

واحدة من أولى العلامات هي توقف المحرك مباشرة بعد البدء, خاصة عندما يكون المحرك باردًا. صمام IAC مسؤول عن زيادة عدد الدورات في الدقيقة المتزايدة قليلاً أثناء البرد في التعويض عن احتكاك الهواء والمحرك الأكثر كثافة. إذا كان الصمام عالقًا أو لا يستجيب, لا ينفذ الهواء غير الكافي إلى مشعب السحب.

توصية: إذا كان المماطلة متسقة, فحص التشخيص (التحقق من رموز مثل p0505) ويُنصح بفحص صمام IAC.

صعوبة إعادة التشغيل بعد المماطلة

بعد كشك غير متوقع, قد يرفع المحرك لكنه فشل في إعادة التشغيل على الفور. قد يظل صمام IAC ملتصقًا مغلقًا, خنق تدفق الهواء الالتفافي اللازم لتحقيق الاستقرار في الخمول.

توصية: محاولة بداية بمساعدة الخانق; لكن, يجب حل المشكلات المستمرة عن طريق تنظيف أو استبدال الصمام.

خشن أو تقلبات RPM في الخمول

قد يكون المحرك منخفضًا جدًا, عالية جدا, أو تتأرجح بين نطاقات RPM (عادة ما بين 600-1200 دورة في الدقيقة). يمكن أن يعطل صمام IAC الذي يستجيب بشكل غير متسق لإشارات وحدة التحكم الإلكترونية توازن الهواء والوقود في الخمول.

توصية: استبعاد أسباب أخرى مثل تسرب الفراغ أو جسم الخانق القذر, ثم اختبر تشغيل صمام IAC.

تحقق من ضوء المحرك مع الرموز المتعلقة بالاتصال

السل (تحقق من ضوء المحرك) قد يتم تشغيله, غالبًا ما تكون مصحوبة برموز مثل P0505 (عطل نظام التحكم في الخمول). تكتشف وحدة التحكم الإلكترونية سرعة الخمول غير السليمة خارج المعلمات المبرمجة بسبب فشل صمام IAC أو تدفق الهواء المقيد.

توصية: استخدم ماسح ضوئي OBD-II لتأكيد رموز الصدع وإجراء تحليل البيانات المباشرة لمقاييس التحكم في الهواء الخاملة.

انخفاض الخمول عند تشغيل الملحقات

تشغيل الأضواء, مكيف الهواء, أو توجيه القوة يسبب انخفاضًا حادًا في دورة في الدقيقة أو تردد محرك. يجب أن يعوض صمام IAC عن زيادة الحمل الكهربائي والميكانيكي. إذا فشلت, لا يمكن للمحرك تثبيت RPM في الخمول.

توصية: مراقبة سلوك الخمول تحت تحميل الملحقات. في حالة حدوث توقف أو قطرات دورة في الدقيقة, النظر في تنظيف IAC أو إعادة المعايرة.

لماذا تفشل صمامات IAC وكيفية منع القضايا المشتركة

فهم الأسباب وراء التحكم في الهواء الخمول (IAC) يمكن أن يساعد فشل الصمام السائقين في منع مشاكل عكس المحرك قبل تصاعدهم. فيما يلي الأسباب الأساسية والتدابير الوقائية القابلة للتنفيذ:

الأسباب الشائعة لفشل صمام IAC

- تراكم الكربون: القضية الأكثر شيوعًا هي تراكم رواسب الكربون والحمأة في مرور صمام IAC. هذه تمنع قدرة الصمام على تنظيم تدفق الهواء, مما يؤدي إلى تقييد التحكم في الخمول.

- الفشل الكهربائي: متأخر , بعد فوات الوقت, قد تتآكل لفائف لفائف IAC الداخلية أو محطات الموصل, قصير, أو كسر, مما أدى إلى تشغيل صمام غير مستجيب.

- آلية الالتصاق: في بعض الحالات, يتم تعليق الصمام جسديًا بسبب التلوث أو عدم الاستخدام, خاصة في المركبات التي تجلس في وضع الخمول لفترات طويلة.

عادات القيادة والصيانة التي تسهم في الفشل

- رحلات قصيرة متكررة: غالبًا ما لا تصل المركبات المستخدمة في العديد من الرحلات القصيرة إلى درجة حرارة المحرك المثلى, تعزيز الرطوبة وتراكم الكربون.

- إهمال صيانة كمية الهواء: يمكن أن يؤدي تجاهل استبدال مرشح الهواء أو تنظيف الجسم الخانق إلى إدخال الملوثات في نظام IAC.

- موسع الخمول: ترك المحرك يعمل لفترات طويلة دون القيادة يزيد من رواسب الكربون حول صمام IAC وجسم الخانق.

تدابير وقائية لتمديد عمر صمام IAC

- أداء تنظيف منتظم: قم بتنظيف صمام IAC وجسم الخانق كل 20،000-30،000 ميل باستخدام عمال النظافة المناسبة.

- فحص الموصلات الكهربائية: تحقق بشكل دوري من التآكل أو الأسلاك الفضفاضة حول تسخير IAC والتوصيل.

- استخدام الجودة للوقود وزيت المحرك: تقليل التغيرات ذات الجودة العالية وتغيرات الزيت في الوقت المناسب من الرواسب الداخلية, تحسين أداء الصمام والاستجابة.

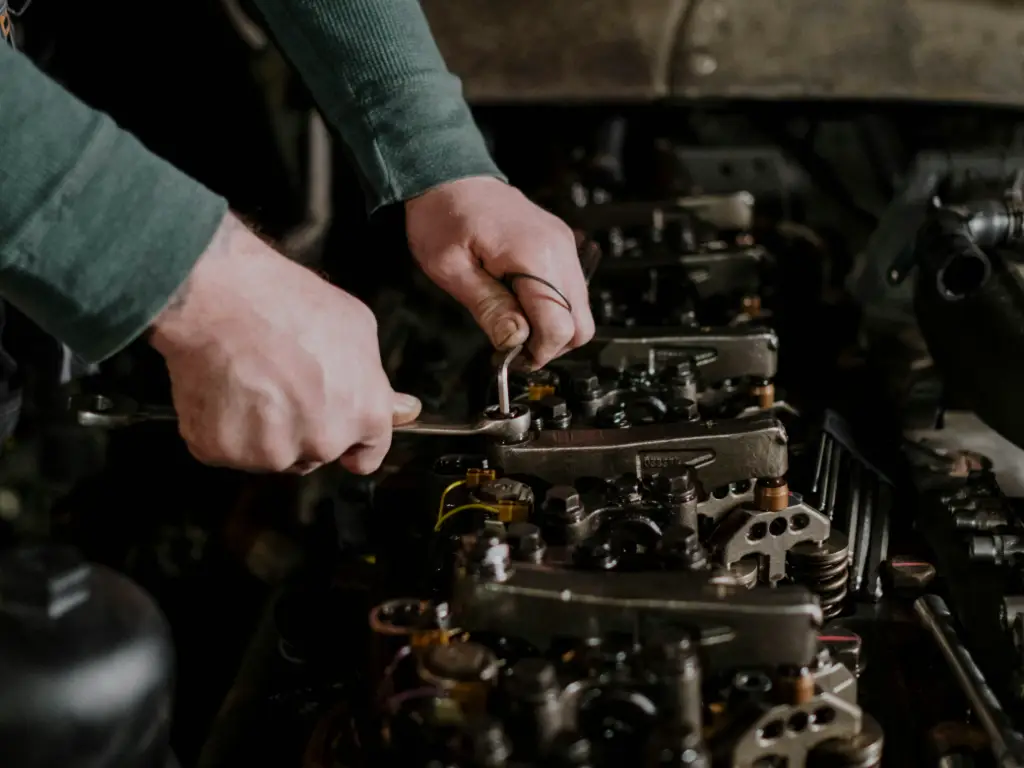

كيفية تشخيص مشاكل صمام IAC: الأدوات والأساليب

يتطلب تشخيص مشكلات صمام IAC بدقة مزيجًا من الفحص البصري, الاختبار الكهربائي, والتحليل الوظيفي لعزل سبب أعطال المرتبطين بالخمول.

- التفتيش البصري

فحص السكن صمام IAC من أجل الأضرار الجسدية, تآكل, أو موصلات كهربائية فضفاضة. افحص خطوط الفراغ القريبة والحشيات للتسربات التي قد تعطل ثبات الخمول.

- التشخيص OBD-II

استخدم ماسح ضوئي OBD-II لاسترداد رموز الصدع-خاصة P0505, الذي يشير إلى عطل نظام التحكم في الهواء الخمول. راقب البيانات المباشرة بحثًا عن عدد دورات في الدقيقة خامل غير منتظم أو ردود فعل غير طبيعية لموضع صمام IAC.

- اختبار المقاومة

استخدم مقياسًا رقميًا لقياس المقاومة عبر محطات الملف اللولبي للصمام. قارن القراءات مع مواصفات الشركة المصنعة لتقييم سلامة الملف.

- اختبار وظيفي

في نماذج معينة, يمكنك تنشيط صمام IAC باستخدام برنامج التشخيص. تحقق يدويًا من حركة pintle لسلس, السفر غير المقيد إذا كان من الممكن الوصول إليه.

- خانق الجسم وتنظيف ممر الهواء

تراكم الكربون يمكن أن يمنع تدفق الهواء. قم بتنظيف منافذ IAC وجسم الخانق للقضاء على العوائق الميكانيكية.

- الملاحظة RPM الخمول

راقب RPM في الخمول أثناء بدء البرد, دورات الاحماء, ومع إكسسوارات مثل A/C أو المصابيح الأمامية يتم تشغيلها لتقييم استجابة IAC تحت الحمل.

يضمن الجمع بين هذه الخطوات التشخيصية تحديدًا دقيقًا للأخطاء المرتبطة بـ IAC, تقليل التخمين وتجنب بدائل الأجزاء غير الضرورية.

تنظيف أو استبدال صمام IAC الخاص بك?

يعتمد تحديد ما إذا كنت تريد تنظيف صمام IAC أو استبداله على شدة الأعراض ونتائج الفحص الأولي. إذا أظهر الصمام تراكمًا طفيفًا للكربون ولكنه يعمل بشكل طبيعي أثناء الاختبار التشخيصي, غالبًا ما يكون التنظيف كافيًا. لكن, إذا كان الصمام معيبًا كهربائيًا, عالقة ميكانيكيا, أو يستمر في التسبب في الخمول غير المستقر بعد التنظيف, عادة ما يكون الاستبدال هو الحل الأكثر موثوقية.

إجراءات التنظيف

- افصل البطارية لمنع حدوث أضرار كهربائية والسماح بإعادة ضبط وحدة التحكم الإلكترونية.

- قم بإزالة صمام IAC بعناية من جسم الخانق, مع ملاحظة أي موضع حشية أو حلقة O.

- فحص الصمام وممرات الهواء لتراكم الكربون أو الحطام.

- رش جسم الخانق أو منظف IAC في منافذ الصمامات واستخدم فرشاة ناعمة أو قطعة قماش لإزالة الملوثات - وتجنب إتلاف العمود الفقري أو المحرك.

- اسمح للصمام أن يجف بالكامل قبل إعادة التثبيت.

- أعد تثبيت الصمام وإعادة توصيل البطارية; ابدأ المحرك واتركه في وضع الخمول لعدة دقائق للسماح للوحدة الإلكترونية بإعادة معايرة إعدادات الخمول.

إذا فشل التنظيف في حل الخمول القاسي أو المماطلة, وخاصة إذا عادت رموز المتاعب التشخيصية إلى الظهور, يوصى باستبدال صمام IAC بوحدة متوافقة مع OEM.

كيفية اختيار واحد مناسب لاستبدال صمام IAC الخاص بك?

يمكن أن يساعدك فهم كيفية مقارنة صمام IAC مع آليات التحكم في الخمول الأخرى في تقييم ما إذا كان الاستبدال هو الحل الأنسب.

| ميزة | صمام IAC | التحكم في الخانق الإلكترونية (إلخ) | خنق موقف الاستشعار (TPS) |

| وظيفة | يتحكم في تدفق الهواء الخمول ميكانيكيا | يتحكم في صفيحة الخانق إلكترونيًا | يقيس وضع الخانق فقط |

| وضع التشغيل | يتجاوز تدفق هواء لوحة الخانق | يضبط فتح الخانق لإدارة الخمول | يرسل بيانات وضع الخانق إلى وحدة التحكم الإلكترونية |

| شائع في | أقدم وبعض المحركات الحالية | معظم المركبات الحديثة | عالمي في المحركات المحقونة الوقود |

| أعراض الفشل | عدم استقرار الخمول, المماطلة | ضعف السيطرة على الخمول, قضايا قابلية القيادة | يؤثر على الخمول بشكل غير مباشر من خلال التحكم في وحدة التحكم الإلكترونية |

| صيانة | التنظيف أو الاستبدال المطلوب | المعايرة الإلكترونية أو الاستبدال | اختبار المستشعر واستبداله |

| دور في السيطرة على الخمول | منظم سرعة الخمول الأساسي | يدمج التحكم في الخمول في شرك الخانق | يوفر إدخال بيانات للتحكم في الخمول |

إذا كانت سيارتك تستخدم صمام IAC مستقل وفشل التنظيف في إصلاح مشكلات الخمول, يعد استبداله بوحدة الجودة حلاً فعالًا من حيث التكلفة وفعال لاستعادة خمول محرك مستقر. عند اختيار بديل, تأكد من التوافق مع صنع سيارتك, نموذج, ونوع وحدة التحكم الإلكترونية.

مجموع الاشتراكات هو خيار موثوق به, تقديم كل من صمامات IAC من فئة OEM وبدائل ما بعد البيع الفعالة من حيث التكلفة, جعلها مناسبة لمستخدمي DIY ومحلات الإصلاح على حد سواء. يغطي خط إنتاجهم مجموعة واسعة من التطبيقات ذات الجودة المتسقة والمتانة المختبرة.