Aftermarket auto parts have become a cornerstone in the automotive industry, offering affordable and reliable alternatives to Original Equipment Manufacturer (تصنيع المعدات الأصلية) parts. These parts are designed and produced by third-party companies, providing consumers with more options when repairing or enhancing their vehicles. The operation of an aftermarket auto parts factory is a fascinating blend of precision engineering, advanced manufacturing techniques, and stringent quality control. This article will take you through the journey from concept to the finished product and explore how these factories play a vital role in the industry.

Overview of Aftermarket Auto Parts Business

The aftermarket auto parts business offers consumers a diverse range of components outside of the original manufacturer’s supply chain. The core of this business model is simple yet expansive: create, distribute, and sell automotive parts. These parts serve as cost-effective alternatives for repairs, replacements, and vehicle upgrades. The aftermarket industry thrives on the ability to provide quality parts at competitive prices, giving vehicle owners more options for maintaining or enhancing their cars.

The business model of aftermarket parts revolves around several key players:

- Manufacturers: These are the factories responsible for designing and producing aftermarket parts. They ensure that their components match the specifications of OEM parts or, in some cases, offer performance enhancements.

- الموزعين: Companies that specialize in distributing aftermarket parts to retailers or directly to consumers. They play a significant role in ensuring that parts are available when and where they are needed.

- تجار التجزئة: These businesses, whether online or brick-and-mortar, sell aftermarket parts directly to customers. They offer a wide selection, often catering to both professional mechanics and DIY enthusiasts.

- Mechanics and Installers: The professionals who install these parts also play a role in promoting aftermarket components, as they often suggest affordable options to car owners during repairs.

Role of Aftermarket Auto Parts Factory

Aftermarket auto parts factories are responsible for producing OEM replacement car parts not made by the original car manufacturer. They focus on replicating or improving OEM parts at a lower cost. These factories design, manufacture, and test parts to ensure they meet industry standards and fit specific vehicles. They handle everything from sourcing raw materials to using machines like CNCs, molding presses, and casting tools to create parts. Quality control is a key part of their operations to ensure safety and durability. Factories also streamline production to keep costs low and meet demand.

How to Manufacture Aftermarket Auto Parts: Factory View

Aftermarket car parts manufacturing is a complex process that requires meticulous planning and execution. Let’s delve into how these factories operate and what makes their production process so essential to the automotive ecosystem.

Set Up the Factory: The First Step to Success

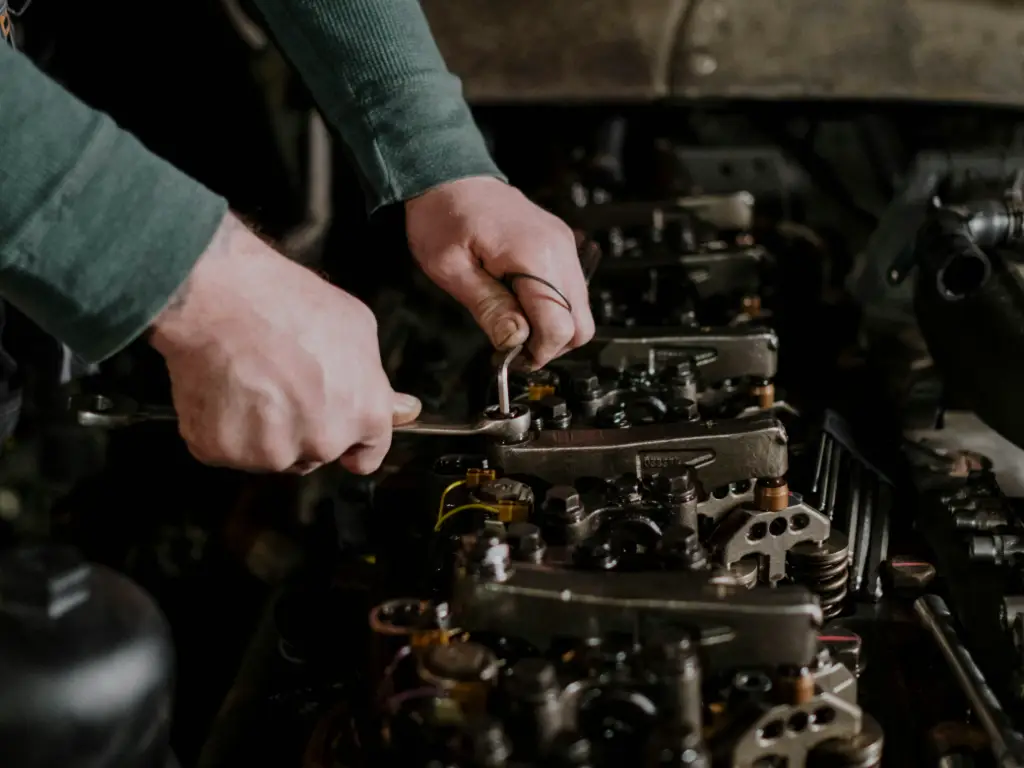

An aftermarket auto parts factory requires substantial investment in specialized machinery, equipment, and materials. These machines are vital for cutting, shaping, and molding metal or plastic materials into the desired forms. Here are the major equipment used in the auto part manufacturing:

- CNC Machines: Computer-controlled machines used for cutting, shaping, and drilling parts with high precision. Essential for producing metal components like brake pads and suspension parts.

- Molding Presses: These machines are used to form plastic and rubber components by pressing heated materials into molds. Commonly used for making gaskets, seals, and other non-metal parts.

- Casting Tools: Equipment used to pour molten metal into molds to create metal parts like engine components and exhaust systems. Vital for high-volume production of durable parts.

- Injection Molding Machines: Used for producing plastic parts by injecting molten plastic into molds. Often employed for making items like bumpers, dashboards, and small plastic components.

- Welding Stations: Used to join metal parts together through various welding techniques. Commonly used in assembling structural components like frames and exhaust systems.

- Heat Treatment Ovens: These are used to harden or temper metal parts, improving their strength and durability. Crucial for parts like gears and shafts that require high resistance to wear.

- Raw Materials: Factories source high-grade metals like steel and aluminum for durability, and plastics or rubber for flexibility and resistance. These materials are essential for producing both metal and non-metal parts.

Design and Prototype: Bring Concepts to Life

CAD (Computer-Aided Design) is used to create precise digital designs of auto parts. Engineers input measurements and specifications to ensure the part meets vehicle requirements. This software helps refine the design before production begins. After CAD design, 3D modeling is used to produce a physical prototype. This allows manufacturers to test the part for fit and performance, making adjustments if needed before mass production.

Fitment refers to how well a part fits on a specific vehicle. Factories use fitment data to ensure the part is compatible with different makes and models. Accurate fitment data prevents installation issues and ensures the part performs as expected. This data is crucial for producing reliable aftermarket parts that match OEM standards.

Manufacturing Process: Step-by-step

The manufacturing process for aftermarket auto parts begins with casting, where molten metal is poured into molds to create components like engine parts and brake discs. After casting, molding shapes materials like plastic and rubber into forms such as gaskets and seals, using injection molding for precise, high-volume production. Following molding, machining (with CNC machines) is employed to cut, drill, and refine parts to exact specifications, ensuring they meet the necessary tolerances for performance and fit. بالإضافة إلى ذلك, techniques like forging (where metal is heated) و welding (which joins metal components together) are used to enhance the strength and complexity of parts, creating robust assemblies and structural components.f parts, creating robust assemblies and structural components.

Quality Control

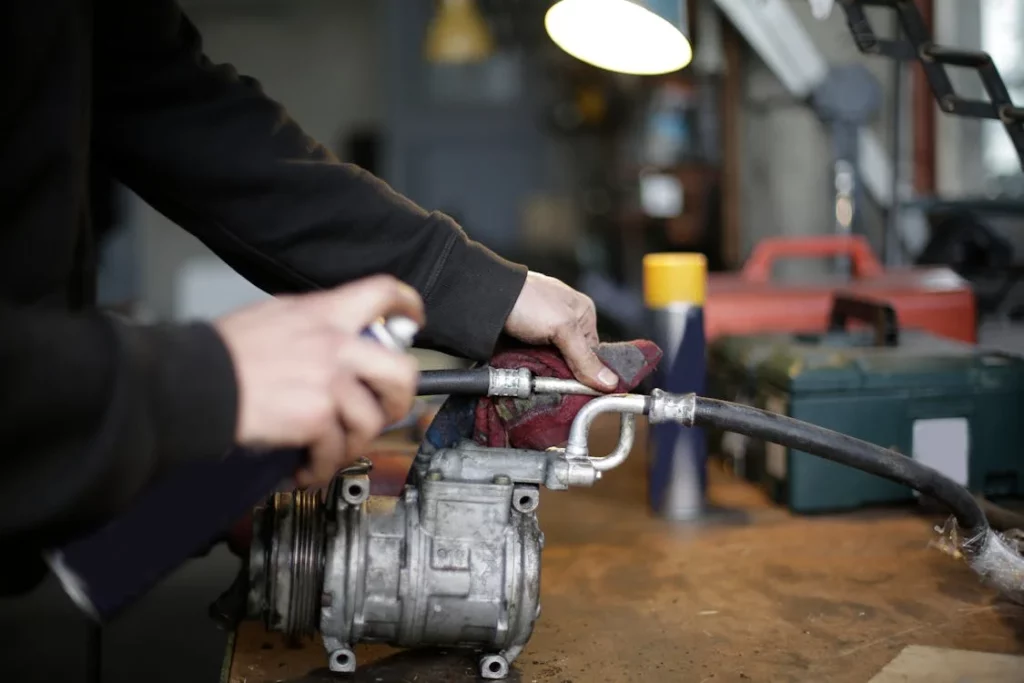

Quality control in aftermarket auto parts manufacturing involves several methods to ensure parts meet performance and safety standards. These comprehensive measures help maintain high standards and ensure the final products are safe and effective for use.

- Visual Inspections: Check for obvious defects or inconsistencies in the appearance of parts.

- Dimensional Testing: Measure parts against specifications to ensure they are within required tolerances.

- Non-Destructive Testing: Use methods like X-ray inspection and ultrasonic testing to detect internal flaws without damaging the parts.

- اختبار وظيفي: Assess how parts perform under real-world conditions to ensure reliability and durability.

- Fatigue Testing: Simulate long-term use to evaluate the part’s endurance and strength.

- Stress Testing: Apply extreme conditions to test the part’s ability to withstand high levels of stress.

Packaging and Labeling

Packaging and labeling are crucial steps in preparing aftermarket auto parts for distribution. Packaging involves using robust materials to shield parts from damage during shipping. This includes custom-fit boxes and protective wraps to prevent scratches and dents. Labeling provides essential details such as part numbers, vehicle compatibility, and installation instructions, often supplemented with barcodes or QR codes for inventory management and easy identification.

بالإضافة إلى ذلك, instructions and warnings are included to guide proper installation and ensure safety. Branding elements, such as company logos and product names, are featured prominently on the packaging to aid in marketing and customer recognition. Some manufacturers also implement environmental considerations by choosing eco-friendly packaging materials and practices to minimize their ecological footprint.

Who Manufactures Aftermarket Parts? 5 Aftermarket Auto Parts Factories Intro

Aftermarket auto parts are populated by numerous leading manufacturers, each contributing to the industry with high-quality components. Here are five of the best aftermarket car parts manufacturers that stand out in the field:

#1 مجموع الاشتراكات

Recognized as a top player in China’s auto parts industry with global reach, مجموع الاشتراكات offers a comprehensive range of aftermarket auto parts with low MOQs, expert brand-building support, and extensive experience. They have 40,000 وحدات SKU, an 8,000㎡ warehouse, و 15 سنوات من الخبرة في التصدير. زائد, they provide services like sourcing, branding support, واللوجستيات, with a focus on quality assurance. They cater to various business types including international agents, retailers, and wholesalers, and provide customization services for packaging and logos.

#2 FMP

Factory Motor Parts (FMP), أنشئت في 1945, has expanded from a single location to over 300 المواقع عبر 35 الدول. Originally part of the Chrysler Mopar Distribution network, FMP serves various automotive aftermarket needs, including dealerships, fleets, retailers, and independent service centers. The company is headquartered in Eagan, MN, and offers various services such as battery programs, online ordering, and fleet supply chain solutions. FMP prides itself on its partnerships with reputable brands and its commitment to exceeding customer needs.

#3 LKQ Corp

LKQ Corporation, أنشئت في 1998, is a leading provider of alternative, specialty, salvage, and recycled auto parts with global operations in North America, Europe, and Taiwan. The company offers a broad range of replacement parts, including remanufactured engines and transmissions. LKQ has expanded through numerous acquisitions and serves diverse markets with a focus on sustainability and customer service. It operates with over 45,000 employees across 1,600 locations and has received accolades for being a responsible company and a great workplace.

#4 The Parts House

TPH offers competitive stocking programs for various auto parts and an online ordering system accessible 24/7. The system requires minimal training and allows users to check prices and availability from multiple branches. TPH also provides extensive training for technicians, both in-person and online, and supports service centers with the Parts Plus Car Care Center program, which offers various business growth features.

#5 Buy Auto Parts

As an auto parts online store, BuyAutoParts excels in delivering auto parts quickly with free shipping on orders over $99 and a one-year warranty on all items. They ensure parts fit exactly and offer easy returns within 60 أيام. With a history dating back to 1989, they provide a wide range of auto parts and accessories, supported by a user-friendly online ordering system. Their professional membership program offers extra discounts and benefits, making them a leading choice for auto parts online.

خاتمة

The operation of an aftermarket auto parts factory is a finely tuned process that requires a blend of innovation, precision, and stringent quality control. These factories are pivotal in providing consumers with cost-effective alternatives to OEM parts, ensuring that vehicles remain in top condition without breaking the bank. As demand for aftermarket parts continues to grow, the industry will no doubt see further advancements in technology and production efficiency, driving the future of automotive repairs and upgrades.

التعليمات

س1: Where are OEM parts made?

OEM parts are manufactured by the original equipment manufacturer, typically in specialized factories that work directly with automotive brands. These factories are often located near automotive production plants to streamline the supply chain.

Q2: Where are most car parts manufactured?

The majority of car parts are manufactured in countries with strong industrial bases, such as China, the United States, ألمانيا, and Japan. These countries have the infrastructure and skilled labor needed to produce both OEM and aftermarket parts.

س3: Who is the largest auto parts supplier in North America?

The largest auto parts supplier in North America is Magna International, a Canadian company known for producing a wide range of parts, including seating systems, body structures, and powertrains for major automakers. The COWTOTAL is the second performer who produces aftermarket car parts.