You might not think about it often, but your car’s oxygen sensor plays a significant role in its daily performance. From ensuring your vehicle runs efficiently to reducing harmful emissions, these sensors help keep everything running smoothly. But what is the function of an oxygen sensor exactly? Let’s dive deeper into how these sensors work and why they are vital to your vehicle’s health.

What Is An Oxygen Sensor: 2 Types Explained

What are O2 sensors in cars? These essential components help monitor and control the vehicle’s engine performance by measuring the oxygen levels in the exhaust. There are two main types of oxygen sensors commonly used: banda estreita e banda larga. Cada tipo desempenha um papel único ajudando a unidade de controle do motor (ECU) regular a mistura ar-combustível para desempenho e eficiência ideais. Vamos explorar as diferenças entre esses dois tipos de sensores.

Banda estreita

Sensores de oxigênio de banda estreita são projetados para monitorar a relação ar-combustível em uma faixa relativamente limitada. Normalmente encontrado em veículos mais antigos, esses sensores fornecem feedback básico para a unidade de controle do motor (ECU) sinalizando se a mistura é rica (muito combustível) ou magro (muito pouco combustível). O sensor de banda estreita opera dentro de uma faixa de tensão de 0.1 para 0.9 volts, flutuando à medida que detecta mudanças nos níveis de oxigênio no escapamento. Embora não seja tão preciso quanto um sensor de banda larga, serve ao seu propósito de manter um equilíbrio aproximado entre eficiência de combustível e controle de emissões.

Banda larga

Sensores de oxigênio de banda larga são mais avançados e fornecem uma gama mais ampla de medições de oxigênio, permitindo um controle mais preciso sobre a relação ar-combustível. Ao contrário dos sensores de banda estreita, que sinalizam apenas misturas ricas ou pobres, sensores de banda larga fornecem, dados precisos sobre os níveis de oxigênio nos gases de exaustão. Isso permite que a ECU faça ajustes mais precisos no sistema de injeção de combustível, melhorando a eficiência do combustível, desempenho do motor, e reduzindo emissões prejudiciais. Esses sensores são normalmente encontrados em veículos mais novos que exigem sistemas de gerenciamento de motor mais precisos.

Como funciona um sensor de oxigênio

O sensor de oxigênio funciona comparando o teor de oxigênio nos gases de exaustão com o teor de oxigênio no ar externo. A ciência por trás deste processo de detecção reside nos materiais utilizados no próprio sensor: Zircônia e Titânia. These materials allow the sensor to create an electrical signal based on the difference in oxygen concentration between the exhaust and the outside air.

Zirconia Sensors

Zirconia oxygen sensors are the most common and work by utilizing a ceramic material that reacts with oxygen. When the sensor is exposed to exhaust gases, the zirconia element creates a voltage signal that corresponds to the amount of oxygen in the gases. This voltage is then sent to the ECU, which adjusts the fuel-to-air ratio accordingly. The more oxygen in the exhaust, the lower the voltage; less oxygen results in a higher voltage. This allows the engine management system to maintain an optimal mixture.

Titania Sensors

Titania sensors, though less common than zirconia, are sometimes used in applications requiring a faster response time. Unlike zirconia sensors, which generate a voltage based on oxygen concentration, titania sensors change their resistance when exposed to varying oxygen levels. The ECU interprets this change in resistance to adjust fuel delivery. Titania sensors are often used in modern vehicles to support improved emissions standards.

What Is the Function of Oxygen Sensor in a Car?

The function of oxygen sensors in a car is multi-faceted, as they are integral to both engine performance and emissions control. Em essência, these sensors monitor and manage the engine’s air-fuel ratio, ensuring that the engine operates efficiently while minimizing environmental impact.

Monitor Air-Fuel Ratio

One of the primary functions of an oxygen sensor is to monitor the air-fuel ratio within the engine. By detecting the oxygen level in the exhaust, o sensor fornece feedback para a ECU, que ajusta a quantidade de combustível injetado na câmara de combustão. Uma relação ar-combustível equilibrada é crítica para alcançar o desempenho ideal do motor, saída de energia, e eficiência de combustível.

Aumente a economia de combustível

Outra função vital do sensor de oxigênio é o seu papel na melhoria da economia de combustível. Ajustando constantemente a mistura ar-combustível para uma combustão ideal, o sensor garante que o motor use combustível de forma mais eficiente. Isso resulta em menor consumo de combustível para a mesma produção, contribuindo para a redução dos custos de combustível ao longo do tempo.

Reduza as emissões prejudiciais

O sensor de oxigênio também desempenha um papel fundamental na redução de emissões prejudiciais. Ao monitorar a relação ar-combustível e garantir uma combustão eficiente, o sensor ajuda a reduzir a produção de poluentes como o monóxido de carbono (CO), hidrocarbonetos (HC), e óxidos de nitrogênio (NOx). This function is essential for meeting stringent environmental regulations and improving air quality.

What Are Symptoms of a Faulty Oxygen Sensor?

When an oxygen sensor becomes faulty, it can cause a variety of issues, including poor engine performance, economia de combustível reduzida, e aumento das emissões. Common symptoms of a faulty oxygen sensor include:

- Illuminated Check Engine Light: A malfunctioning oxygen sensor will trigger the check engine light, alerting the driver to a potential issue.

- Poor Fuel Efficiency: Se o sensor não estiver fornecendo dados precisos, the ECU may inject too much fuel into the engine, leading to decreased fuel economy.

- Rough Engine Idle or Misfires: A faulty sensor can result in erratic engine behavior, such as rough idling or engine misfires.

- Aumento de emissões: A failing oxygen sensor may lead to higher-than-normal emissions, which can cause the vehicle to fail emissions testing.

What Does O2 Sensor Circuit Malfunction Mean?

An O2 sensor circuit malfunction typically indicates a problem with the electrical connection or signal from the oxygen sensor. This can be caused by damaged wiring, corroded connectors, or a faulty sensor itself. When the circuit malfunctions, the ECU cannot receive accurate oxygen data, leading to improper fuel management and, eventually, engine performance issues. A diagnostic trouble code (DTC) will usually be stored in the vehicle’s onboard computer, which can be retrieved using a scan tool to pinpoint the exact issue.

How to Maintain and Replace Oxygen Sensors?

The function of oxygen sensors is critical to maintaining your vehicle’s performance and reducing emissions. Ao longo do tempo, these sensors can wear out due to exposure to high temperatures, contaminantes, or general aging. Regular maintenance and timely replacement are key to ensuring they continue working efficiently. Here’s how to properly maintain and replace your oxygen sensors.

Maintenance Tips

- Verifique se há vazamentos de exaustão: Small exhaust leaks can lead to incorrect readings from the oxygen sensor. Inspect your exhaust system regularly for any cracks or holes that could interfere with sensor accuracy.

- Regular Engine Tune-Ups: Keep your engine running smoothly with routine maintenance, such as changing the air filter and replacing worn fuel injectors. This helps reduce strain on the oxygen sensor and can extend its lifespan.

- Keep the Engine Temperature in Check: High temperatures can damage the oxygen sensor over time. Avoid overheating the engine by monitoring the coolant levels and ensuring the radiator is working efficiently.

- Avoid Contaminants: Keep fuel and exhaust systems clean. Contaminants like oil or antifreeze can poison the oxygen sensor, leading to false readings and premature failure.

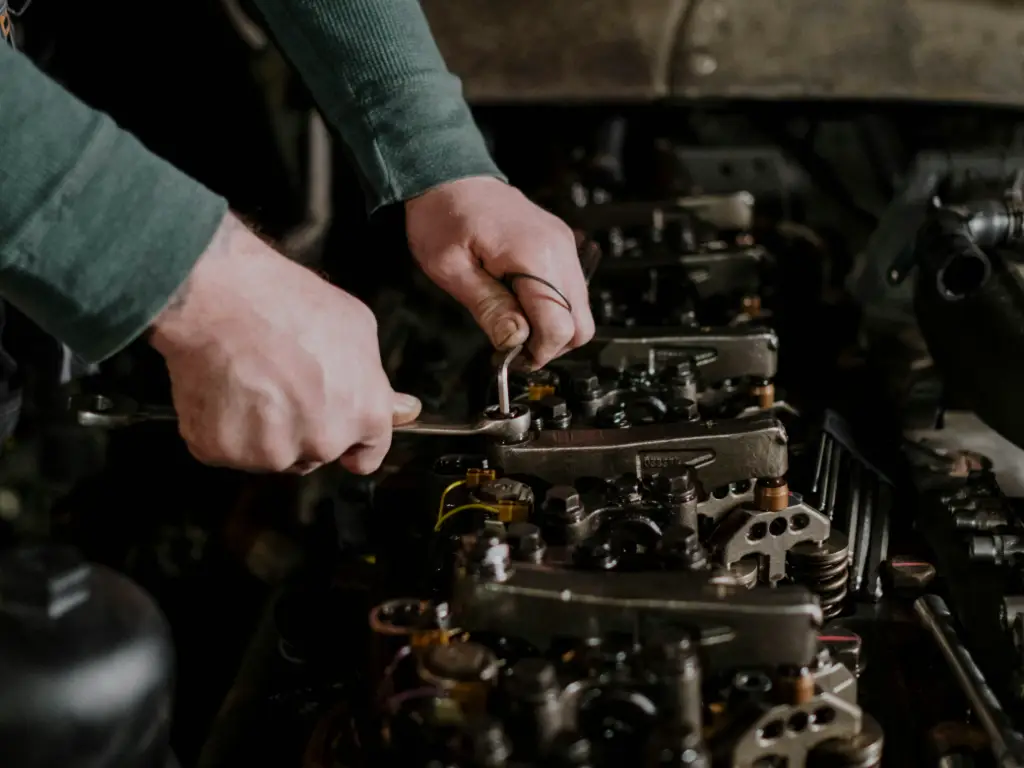

Replacement Instructions

- Locate the Sensor: Oxygen sensors are typically located along the exhaust pipe, antes ou depois do conversor catalítico. Refer to your vehicle’s manual to find the exact location.

- Disconnect the Battery: Before removing the sensor, disconnect the vehicle’s battery to avoid electrical shock and to prevent triggering error codes.

- Remove the Faulty Sensor: Use a wrench or specialized oxygen sensor socket to carefully unscrew and remove the old sensor. Anote a posição do sensor para o correto posicionamento do novo.

- Instale o novo sensor: Rosqueie o novo sensor no lugar, garantindo que esteja apertado com segurança, mas não apertado demais. Reconecte o conector elétrico.

- Reconecte a bateria: Depois de instalar o novo sensor, reconecte a bateria e limpe quaisquer códigos de erro usando um scanner OBD-II. Faça um teste de direção do veículo para garantir que o sensor esteja funcionando corretamente.

Conclusão

Resumidamente, o domínio de qual é a função de um sensor de oxigênio ajuda a manter uma relação ar-combustível equilibrada, aumentar a eficiência de combustível, minimizar emissões, e proteja seu motor contra danos. Se você estiver percebendo problemas de desempenho ou economia de combustível, talvez seja hora de verificar seu sensor de oxigênio. A manutenção regular pode garantir que seu carro permaneça em perfeitas condições por muitos anos.