| Makes | Series | Models | Year |

|---|

Have multiple nozzles to achieve better atomization.

Feature a single nozzle for specific applications.

Mounted in the intake manifold, spraying fuel before the intake valve, suitable for multipoint injection systems.

Directly installed in the cylinder, spraying fuel directly into the combustion chamber, suitable for direct-injection engines.

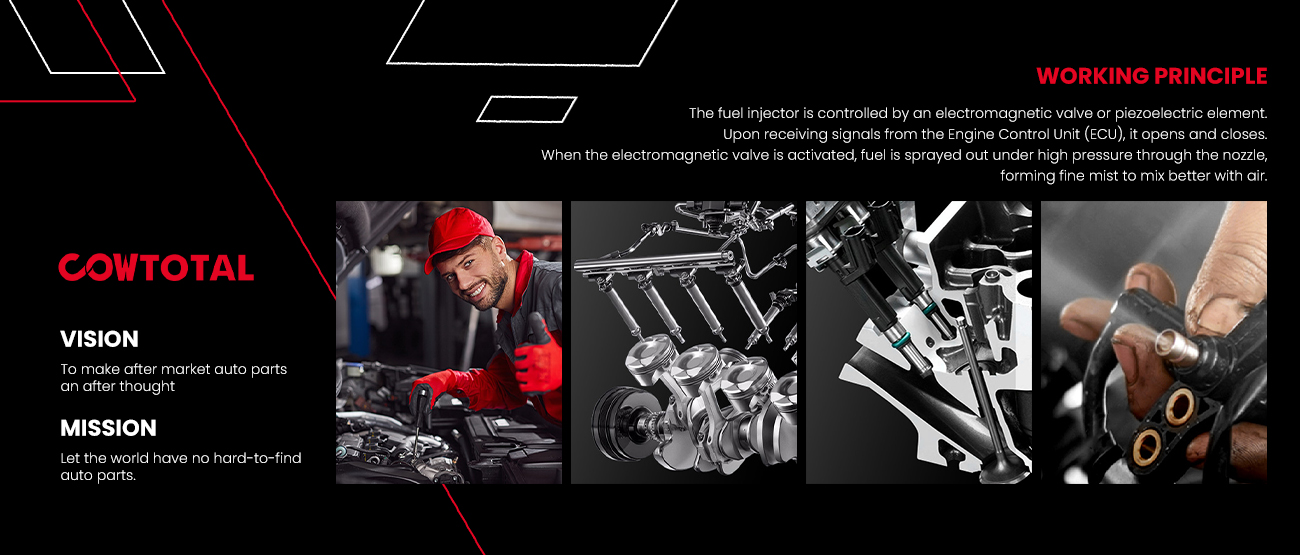

A fuel injector is a crucial component in the engine’s fuel system, responsible for injecting fuel into the combustion chamber or intake manifold at specific times and in precise amounts. This ensures that the fuel mixes thoroughly with the air for optimal combustion. The design and performance of the fuel injector significantly affect the engine’s efficiency, power output, fuel economy, and emission characteristics.

In modern engine systems, fuel injector technology continues to advance with the aim of improving fuel efficiency, reducing emissions, and enhancing engine performance. For instance, high-pressure direct injection technology and the latest electromagnetic valve control technology enable fuel injectors to spray finer fuel mist in a shorter time at higher pressure, achieving efficient combustion.

![]()

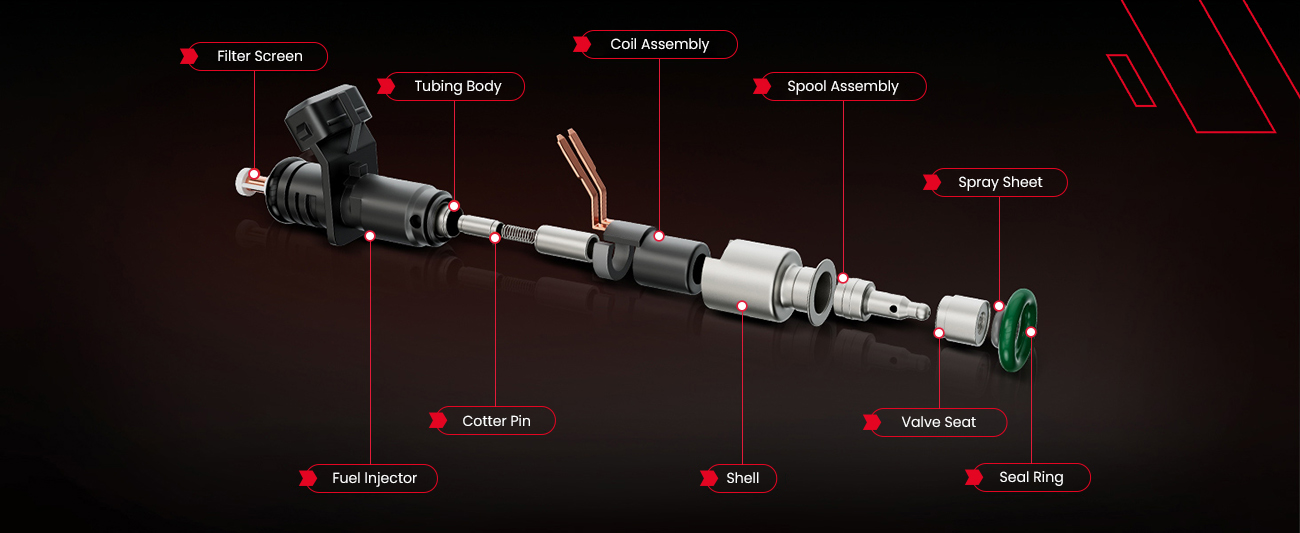

Material: Usually made from high-wear, high-pressure resistant stainless steel or special alloys.

Shape: Cylindrical design with internal fuel channels.

Function: Controls the opening and closing of the injection orifice, directly affecting the injection volume and spray characteristics.

Material: High-strength, wear-resistant alloy.

Structure: Needle-shaped or cylindrical; designed for single-point or multi-point injection as needed.

Quantity: Ranges from 2 to 12, depending on engine design requirements.

Diameter: Usually between 0.1 to 0.4 millimeters.

Role: Ensures atomization and uniform distribution through high-pressure fuel injection.

Function: Drives the needle valve movement via electromagnetic force.

Parameters: Coil resistance is typically 10 to 15 ohms (high resistance injectors) or less than 3 ohms (low resistance injectors); operating voltage is 12 volts.

Material: High-strength stainless steel or special alloy.

Role: Transmits the electromagnetic coil force to the needle valve.

Function: Keeps the needle valve in the closed position when there is no electric current.

Parameters: Spring strength is matched to the injection pressure to ensure stable performance under high pressure.

Material: High-temperature, corrosion-resistant rubber or polymer.

Function: Prevents fuel leakage and ensures system sealing.

Electrical Connector: Connects to the power supply and control signals.

Fuel Connector: Connects to the fuel supply system, typically quick-connect or threaded.

Structure: Usually made from metal or alloy material.

Function: Secures the injector in place on the engine, ensuring accurate injection direction.

Function: Filters the fuel entering the injector to prevent impurities from clogging the orifice.

Location: Typically positioned at the fuel inlet of the injector.

In summary, the structural components of a fuel injector closely cooperate to ensure it can efficiently and accurately complete the fuel injection task. Understanding the structure of the injector helps in better maintenance and optimization of engine performance.

![]()

COWTOTAL fuel injectors provide exceptional precision and reliability, offering improved fuel efficiency, reduced emissions, and enhanced engine performance to meet the demanding needs of modern vehicles.When choosing fuel injectors, it is essential to comprehensively consider the vehicle type, engine performance requirements, and specific working conditions.

![]()

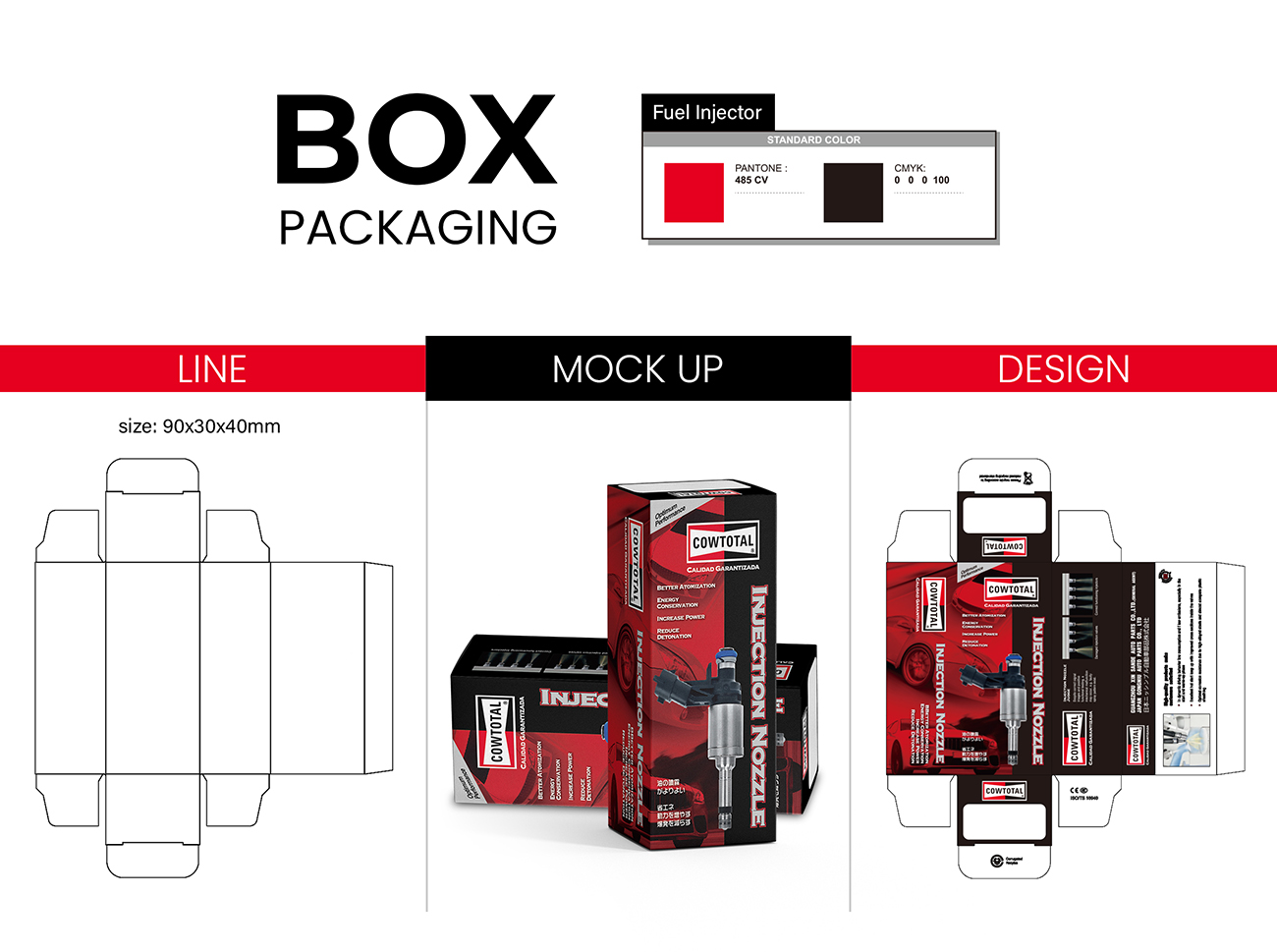

Whether you’re starting from scratch or looking to refresh your existing image, our team of design experts will work closely with you to create a logo and packaging that reflects your unique vision.

![]()

Copyright © 2024, COWTOTAL. All rights reserved.