Every vehicle owner knows that keeping your car in top shape is crucial for a smooth ride and better fuel efficiency. One often overlooked component that plays a significant role in this is the oxygen sensor. In this auto part blog, we’ll delve into the intricacies of O2 sensors, focusing specifically on the differences between O2 sensors downstream vs upstream. By understanding how these sensors operate and their impact on your vehicle, you can make informed decisions that enhance performance and reduce emissions.

What Are O2 Sensors in Cars?

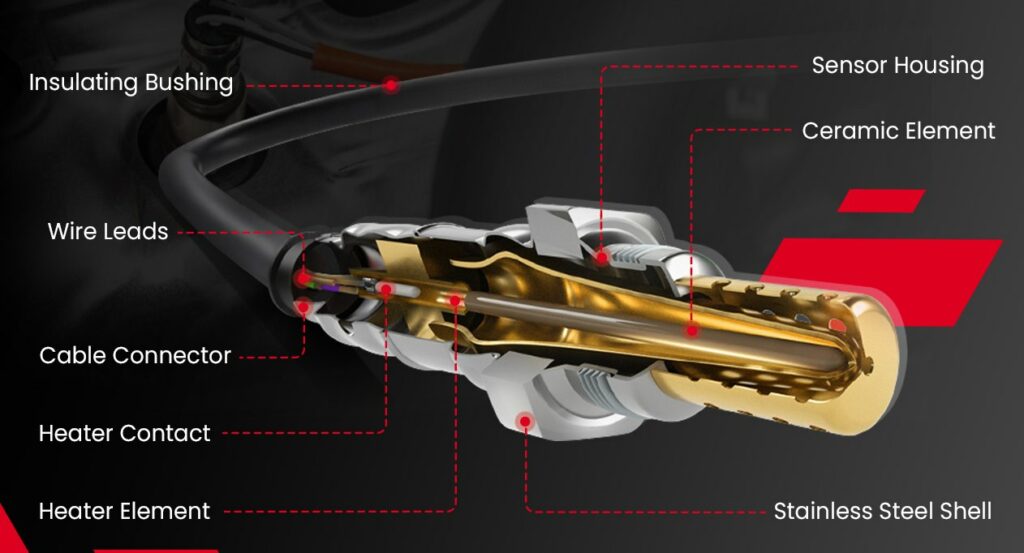

Oxygen (O2) sensors are critical components in a vehicle’s emission control system. They monitor the level of oxygen in the exhaust gases, providing real-time feedback to the engine control unit (ECU). This data is essential for optimizing fuel efficiency and reducing harmful emissions. There are typically two types of O2 sensors: upstream (pre-catalytic converter) and downstream (post-catalytic converter). Each plays a distinct role in ensuring the engine runs efficiently and meets regulatory emission standards.

What Does Upstream and Downstream Oxygen Sensor Mean?

The terminology “upstream” and “downstream” refers to the sensor’s position relative to the catalytic converter.

An upstream O2 sensor is positioned before the catalytic converter, monitoring the oxygen content in the exhaust gases exiting the engine. This information helps the ECU adjust the air-fuel mixture for optimal combustion.

Conversely, the downstream O2 sensor, situated after the catalytic converter, assesses the efficiency of the catalytic converter by measuring the oxygen levels in the exhaust gases that have passed through it. This setup allows for a comprehensive understanding of the engine’s performance and the effectiveness of the emissions system.

What Are O2 Sensors For?

O2 sensors serve several crucial functions in modern vehicles. It can:

- Monitor oxygen levels in exhaust gases.

- Optimize air-fuel mixture for efficient combustion.

- Reduce harmful emissions from the vehicle.

- Improve fuel efficiency and gas mileage.

- Provide feedback for engine control adjustments.

- Help diagnose issues in the emissions system.

What’s the Difference: O2 Sensor Downstream vs Upstream

The difference between an O2 sensor upstream or downstream goes beyond location. These sensors have unique roles that impact engine performance and emissions control. Understanding their distinctions can help in diagnosing and maintaining your vehicle’s efficiency.

Location

An upstream sensor is located before the catalytic converter, typically in the exhaust manifold. A downstream sensor is placed after the catalytic converter, usually in the exhaust pipe.

Function

The upstream sensor monitors the air-fuel mixture for combustion. The downstream sensor evaluates the catalytic converter’s efficiency by checking oxygen levels post-conversion.

Voltage

What should O2 sensor voltage be? The upstream sensor fluctuates between 0.1 to 0.9 volts. The downstream sensor usually maintains a more stable voltage, around 0.45 volts when the catalytic converter functions correctly.

Signal to ECU

The upstream sensor sends data to adjust the air-fuel mixture in real time. The downstream sensor signals the ECU to confirm if the catalytic converter is reducing emissions effectively.

Impact on Performance

A faulty upstream sensor can cause poor fuel efficiency, reducing mileage by up to 40%. A failing downstream sensor may not trigger engine issues immediately but can allow higher emissions.

Are They Interchangeable?

No, O2 sensors upstream and downstream are not interchangeable. Each sensor has a specific role and is calibrated differently. Installing the wrong sensor can lead to incorrect readings, affecting fuel efficiency and emissions control. You may always ensure the correct sensor is used for its designated position in the exhaust system.

How to Tell Which Oxygen Sensor Is Bad?

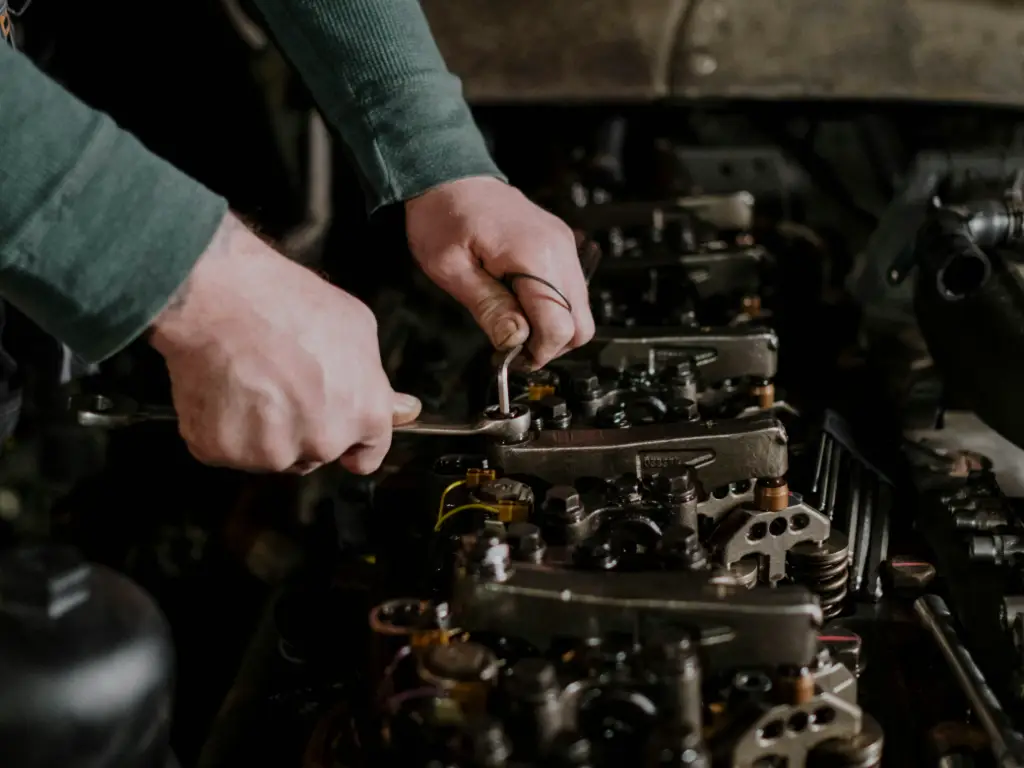

You can identify a failing O2 sensor through diagnostic tools and observable symptoms. Common signs of a malfunctioning sensor include poor fuel economy, rough engine performance, and the illumination of the check engine light. An OBD-II scanner can provide specific trouble codes related to the O2 sensors, aiding in pinpointing the faulty unit. Additionally, a visual inspection may reveal physical damage or signs of wear, further assisting in the diagnosis.

What Causes an Oxygen Sensor to Fail?

Several factors can contribute to the failure of an O2 sensor, whether upstream or downstream. These sensors face harsh conditions in the exhaust system, and failure often leads to noticeable symptoms. Here are the primary causes of O2 sensor failure, along with their warning signs.

Contamination

Oil or coolant leaks can coat O2 sensors, leading to inaccurate readings and failure. Contaminated sensors may cause rough idling, poor fuel economy, or increased emissions.

Wear and Tear

O2 sensors typically last 60,000 to 90,000 miles. As they wear out, signs include reduced fuel efficiency, sluggish acceleration, and the check engine light turning on.

Excessive Heat

Exhaust temperatures exceeding 1,000°F can degrade sensors, especially upstream. This damage may result in erratic engine performance and engine misfires.

Electrical Issues

Faulty wiring or corroded connectors prevent accurate signals to the ECU. Symptoms include inconsistent engine behavior, a sudden drop in fuel economy, or intermittent check engine light warnings.

Carbon Buildup

Incomplete combustion can cause carbon deposits on O2 sensors, particularly downstream. Signs include delayed sensor response, engine hesitation, or a persistent check engine light.

What Will Happen If Oxygen Sensor Is Not Working?

A non-functional O2 sensor can have several detrimental effects on vehicle performance and emissions. Without accurate oxygen readings, the ECU may adjust the air-fuel mixture incorrectly, leading to decreased fuel efficiency and increased exhaust emissions. This harms the environment and triggers the check engine light. In severe cases, prolonged operation with a faulty sensor can damage other components, including the catalytic converter, leading to costly repairs.

Which O2 Sensor Goes Bad First: Upstream or Downstream?

Typically, the upstream O2 sensor is more prone to failure than the downstream sensor. This increased vulnerability is due to its proximity to the combustion process, where it is constantly exposed to extreme temperatures and fluctuating exhaust conditions. However, the downstream sensor can also fail, particularly if it has to compensate for an upstream sensor malfunction or if the catalytic converter is not functioning optimally.

Can You Drive with a Bad O2 Sensor? Shall I Replace Them?

While it is possible to drive with a malfunctioning O2 sensor, doing so is not advisable. A faulty sensor can lead to poor fuel economy, increased emissions, and potentially serious engine problems. It is prudent to address any issues with O2 sensors promptly to avoid further complications. Replacement of a bad sensor is often a straightforward process and can significantly improve vehicle performance and emissions.

How to Find the Best O2 Sensor Brands?

Finding the best O2 sensor brands requires careful consideration of several factors:

- Look for brands with a proven track record in the automotive industry.

- Choose manufacturers offering O2 sensors that meet OEM specifications.

- Ensure the brand provides a warranty for their sensors.

- Check for reviews and feedback from professional mechanics and users.

- Opt for brands that use high-quality materials to ensure durability.

For a reliable option, consider COWTOTAL, a trusted oxygen sensor manufacturer that provides custom services such as branding and labeling. They offer wholesale options in bulk for brand owners, repair shops, or other big or small auto part businesses, ensuring high-quality standards in every sensor produced.

How Much Is an O2 Sensor for Replacement?

The cost of replacing an O2 sensor can vary significantly based on the vehicle make and model, as well as the specific sensor required. On average, the price for an O2 sensor can range from $50 to $200 for the part alone. Labor costs for installation may add an additional $50 to $150, depending on the complexity of the job. Overall, vehicle owners can expect to spend between $100 and $350 for a complete O2 sensor replacement.

Conclusion

In summary, knowing the differences between O2 sensor downstream vs upstream is essential for optimizing your vehicle’s performance and reducing harmful emissions. By addressing any sensor issues promptly, you can enhance fuel efficiency and prolong the life of your engine. If you suspect problems with your O2 sensors, it’s wise to consult a professional mechanic to ensure your vehicle runs as efficiently as possible.

FAQ

Q1: What Can a Bad Downstream O2 Sensor Cause?

A malfunctioning downstream O2 sensor can lead to incorrect readings of catalytic converter performance. This may result in unmonitored emissions issues, potentially causing the check engine light to illuminate. If left unchecked, it can contribute to further degradation of the catalytic converter, leading to costly repairs and increased environmental impact.

Q2: What Voltage Should Upstream O2 Sensor Read?

The upstream O2 sensor typically oscillates between 0.1 and 1.0 volts, reflecting real-time changes in the exhaust gases. A healthy sensor should display frequent fluctuations within this range, signaling effective performance.

Q3: What Should a Downstream O2 Sensor Read?

The downstream O2 sensor usually operates within a similar voltage range as the upstream sensor, typically around 0.45 volts.